Chart Industries Components: A Deep Dive Into Cryogenic Gear Parts

By admin / July 27, 2024 / No Comments / 2025

Chart Industries Components: A Deep Dive into Cryogenic Gear Parts

Associated Articles: Chart Industries Components: A Deep Dive into Cryogenic Gear Parts

Introduction

With enthusiasm, let’s navigate by the intriguing matter associated to Chart Industries Components: A Deep Dive into Cryogenic Gear Parts. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Chart Industries Components: A Deep Dive into Cryogenic Gear Parts

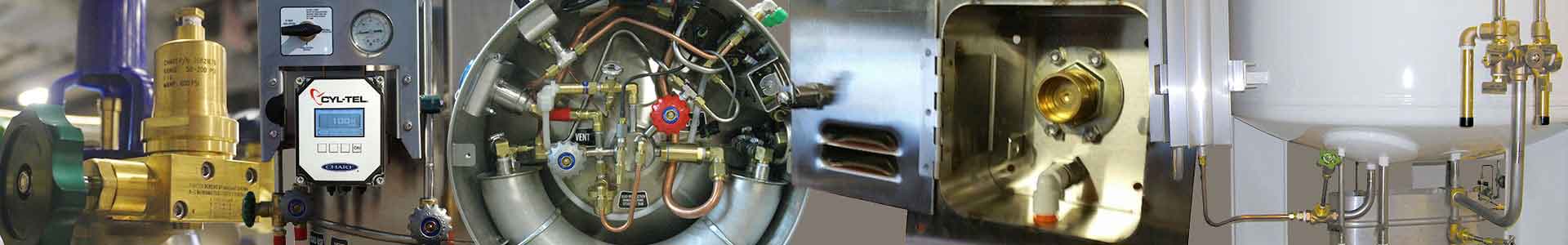

Chart Industries is a worldwide chief within the design, manufacture, and servicing of extremely engineered gear for the cryogenic and industrial gasoline industries. Their merchandise are important to varied sectors, together with power, healthcare, and industrial manufacturing, enabling the secure and environment friendly dealing with of liquefied gases like oxygen, nitrogen, argon, helium, and pure gasoline. Whereas Chart Industries is thought for its full programs, understanding the person elements – the Chart Industries components – is essential to appreciating the corporate’s technological prowess and the reliability of its gear.

This text delves into the various world of Chart Industries components, exploring their functions, supplies, manufacturing processes, and significance in sustaining operational effectivity and security throughout a spread of cryogenic functions.

I. Core Parts and Their Purposes:

Chart Industries’ components catalog is in depth, encompassing a variety of elements important to the efficiency of their cryogenic gear. These may be broadly categorized as follows:

A. Stress Vessels and Tanks: These type the guts of most cryogenic programs, designed to resist excessive pressures and temperatures. Chart Industries produces varied varieties, together with:

-

Double-walled tanks: Providing superior insulation and minimizing boil-off, these are essential for long-term storage and transportation of cryogenic liquids. The design incorporates vacuum insulation, usually with a perlite or powder fill, to keep up cryogenic temperatures. The internal and outer shells are sometimes constructed from high-strength stainless-steel.

-

Single-walled tanks: Less complicated in design and sometimes used for smaller-scale functions or conditions the place weight is a big issue. These depend on exterior insulation and are often much less efficient at minimizing boil-off in comparison with double-walled tanks.

-

Cryogenic storage tanks: Ranging in measurement from small dewars to huge storage vessels, these are designed for particular cryogenic fluids and operational necessities. They usually incorporate superior options like stress reduction valves, degree sensors, and vacuum monitoring programs.

-

Transport tanks: Particularly engineered for the secure and environment friendly transportation of cryogenic liquids by way of highway, rail, or sea. These tanks incorporate strong designs, strong mounting programs, and security options to resist the pains of transportation.

B. Valves and Fittings: Exact management and secure dealing with of cryogenic fluids are paramount. Chart Industries gives a complete vary of valves and fittings, together with:

-

Cryogenic valves: These valves are particularly designed to function reliably at extraordinarily low temperatures, usually incorporating specialised seals and supplies to stop leakage. Frequent varieties embody ball valves, gate valves, and globe valves, every fitted to particular functions.

-

Fittings: These join varied elements of the cryogenic system, making certain a leak-free and safe connection. Fittings are sometimes produced from supplies appropriate with cryogenic fluids and designed to resist the intense temperatures and pressures. Frequent varieties embody flanges, unions, and adaptors.

-

Stress reduction valves: Important security elements designed to stop over-pressurization of the system, defending towards potential catastrophic failures. These valves are calibrated to open at a selected stress, releasing extra stress to keep up system integrity.

C. Insulation and Vacuum Techniques: Sustaining cryogenic temperatures is essential for environment friendly operation. Chart Industries makes use of superior insulation and vacuum programs:

-

Vacuum insulation: An important facet of double-walled tanks, vacuum insulation considerably reduces warmth switch, minimizing boil-off and maximizing the storage lifetime of cryogenic liquids. The vacuum is maintained by getters, which take up any residual gases.

-

Insulation supplies: Numerous insulation supplies are used, together with perlite, silica aerogel, and polyurethane foam, every providing completely different ranges of thermal efficiency and cost-effectiveness. The selection of insulation depends upon the particular software and required efficiency traits.

D. Instrumentation and Controls: Exact monitoring and management are important for secure and environment friendly operation. Chart Industries provides a spread of instrumentation and management elements, together with:

-

Degree sensors: Precisely measure the extent of cryogenic liquid inside the tank, offering important data for operational administration.

-

Temperature sensors: Monitor the temperature of the cryogenic liquid, making certain it stays inside the desired vary.

-

Stress sensors: Monitor the stress inside the system, offering early warning of potential stress build-up.

-

Management programs: Combine varied sensors and actuators to automate the operation of the cryogenic system, optimizing effectivity and security.

II. Supplies and Manufacturing Processes:

The supplies utilized in Chart Industries components are rigorously chosen to resist the intense situations of cryogenic functions. Frequent supplies embody:

-

Chrome steel: Excessive-strength stainless-steel alloys, comparable to 304L and 316L, are broadly used on account of their glorious corrosion resistance and cryogenic toughness. These alloys keep their energy and ductility at extraordinarily low temperatures.

-

Aluminum alloys: In some functions, aluminum alloys are used on account of their lighter weight, though their cryogenic properties could also be much less strong than stainless-steel.

-

Speciality polymers: Sure polymers, comparable to PTFE (polytetrafluoroethylene) and different fluoropolymers, are used for seals and gaskets on account of their glorious chemical resistance and low temperature efficiency.

Manufacturing processes employed by Chart Industries are subtle and exactly managed to make sure the standard and reliability of their components. These processes embody:

-

Forging: Used to create high-strength elements, forging imparts superior mechanical properties to the supplies.

-

Welding: Precision welding methods are used to affix varied elements, making certain leak-free and strong connections. Superior welding processes, comparable to TIG (Tungsten Inert Fuel) welding, are sometimes employed.

-

Machining: Exact machining processes are used to create elements with tight tolerances, making certain correct match and performance.

-

Warmth remedy: Warmth remedy processes are used to boost the mechanical properties of supplies, enhancing energy, ductility, and resistance to cryogenic embrittlement.

-

Non-destructive testing (NDT): Rigorous NDT strategies, comparable to ultrasonic testing and radiographic inspection, are employed to make sure the integrity of the manufactured components and establish any potential defects.

III. Significance of Real Chart Industries Components:

Utilizing real Chart Industries components is essential for a number of causes:

-

Security: Real components are designed and manufactured to satisfy the stringent security necessities of cryogenic functions. Utilizing counterfeit or substandard components can compromise security and result in catastrophic failures.

-

Reliability: Real components are manufactured to exacting specs, making certain constant efficiency and reliability. Substandard components might fail prematurely, resulting in downtime and elevated upkeep prices.

-

Guarantee: Utilizing real components ensures that the guarantee on the gear stays legitimate. Utilizing non-genuine components can void the guarantee.

-

Efficiency: Real components are optimized for the particular cryogenic gear, making certain optimum efficiency and effectivity.

-

Compatibility: Real components are assured to be appropriate with the gear, making certain correct match and performance.

IV. Conclusion:

Chart Industries components are important elements within the secure and environment friendly operation of cryogenic gear throughout varied industries. Understanding the variety of those elements, the supplies used, and the manufacturing processes concerned is essential for appreciating the technological sophistication and reliability of Chart Industries’ merchandise. Using real Chart Industries components is paramount to making sure the security, reliability, and efficiency of cryogenic programs, in the end defending each personnel and investments. Selecting real components ensures optimum operational effectivity, minimizes downtime, and protects towards doubtlessly hazardous conditions related to cryogenic functions. The longevity and dependability of Chart Industries gear are intrinsically linked to the standard and integrity of its particular person elements, highlighting the significance of prioritizing real components for all upkeep and restore wants.

Closure

Thus, we hope this text has offered worthwhile insights into Chart Industries Components: A Deep Dive into Cryogenic Gear Parts. We hope you discover this text informative and useful. See you in our subsequent article!