Decoding Schedule 40 Pipe: A Complete Information To Thickness Charts And Purposes

By admin / June 21, 2024 / No Comments / 2025

Decoding Schedule 40 Pipe: A Complete Information to Thickness Charts and Purposes

Associated Articles: Decoding Schedule 40 Pipe: A Complete Information to Thickness Charts and Purposes

Introduction

With enthusiasm, let’s navigate by means of the intriguing subject associated to Decoding Schedule 40 Pipe: A Complete Information to Thickness Charts and Purposes. Let’s weave fascinating info and supply contemporary views to the readers.

Desk of Content material

Decoding Schedule 40 Pipe: A Complete Information to Thickness Charts and Purposes

Schedule 40 pipe, a ubiquitous presence in plumbing, industrial functions, and development, is outlined by its standardized wall thickness. Understanding this thickness is essential for choosing the suitable pipe for a given utility, guaranteeing structural integrity, and adhering to security rules. This text delves into the intricacies of Schedule 40 pipe thickness charts, explaining their interpretation, the components influencing thickness variations, and the sensible implications for varied industries.

Understanding Schedule 40 Designation:

The "Schedule" designation for pipe refers to its wall thickness relative to its nominal diameter. Schedule 40 is a standard commonplace, representing a stability between power and cost-effectiveness. It isn’t a direct measurement of wall thickness however fairly a standardized system based mostly on a components that considers the pipe’s inside diameter and the specified stress score. Completely different schedules, similar to Schedule 80 (thicker) and Schedule 40S (thinner), exist, every providing various levels of stress resistance and wall thickness.

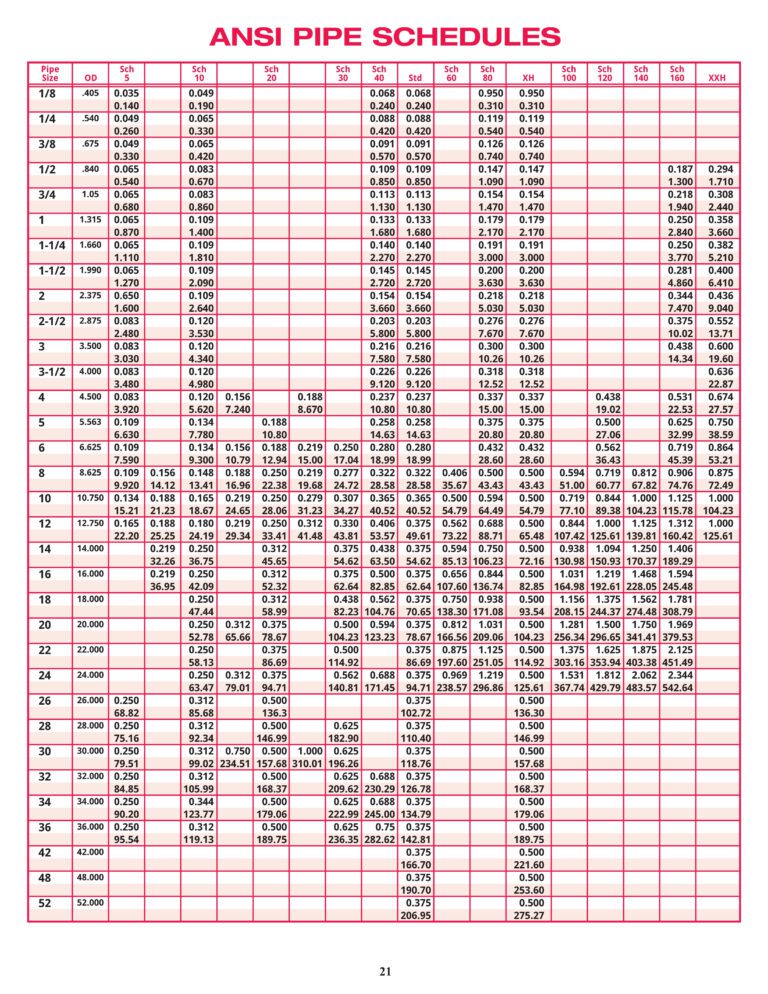

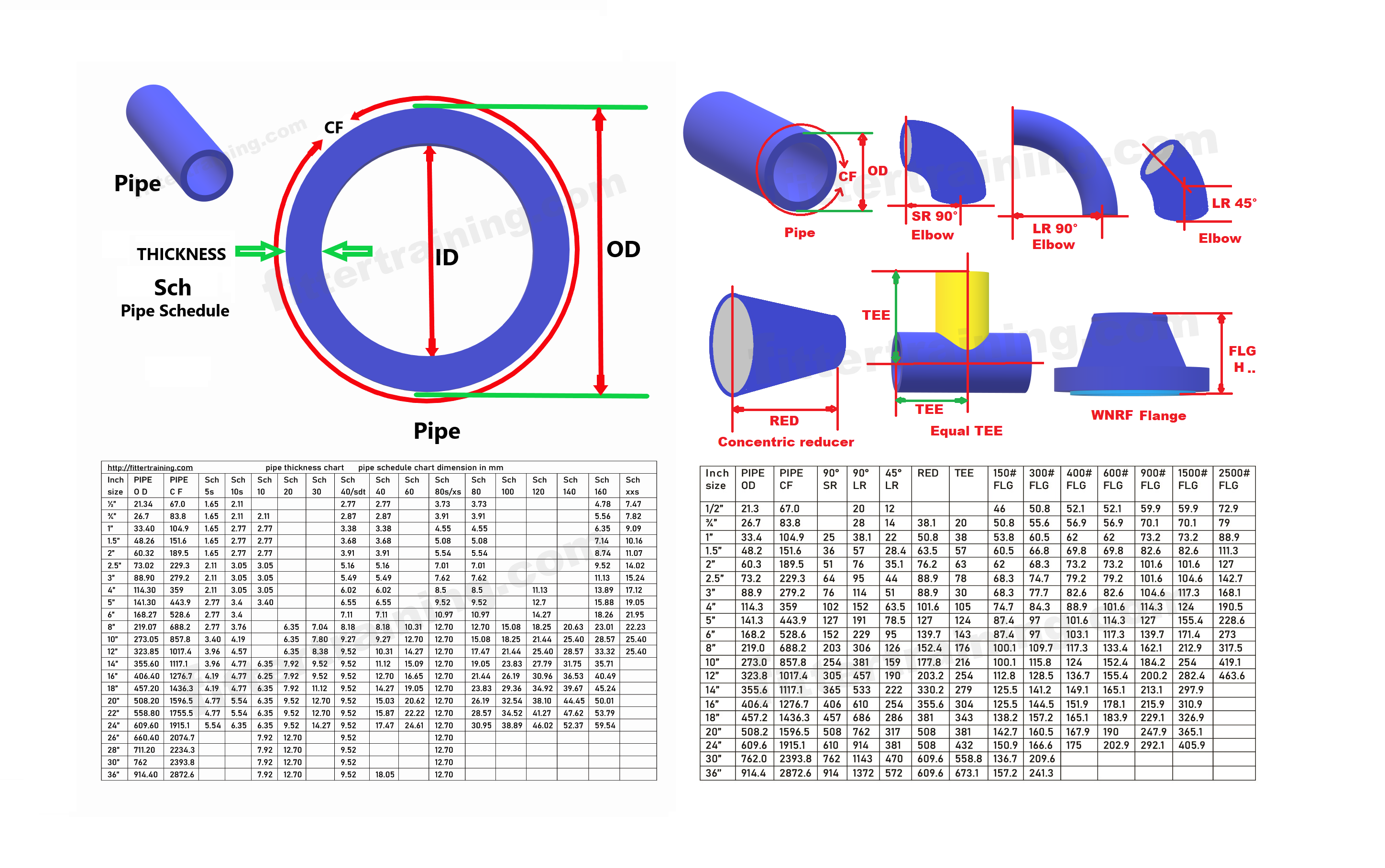

Decoding Schedule 40 Pipe Thickness Charts:

Schedule 40 pipe thickness charts sometimes current knowledge in tabular format. These charts often checklist the nominal pipe dimension (NPS), the precise exterior diameter (OD), and the corresponding wall thickness (WT) in inches or millimeters. It is important to notice that the NPS will not be the precise inside diameter (ID); it is a nominal dimension used for identification and standardization. The precise ID could be calculated by subtracting twice the wall thickness from the OD.

A Pattern Chart Snippet (Illustrative):

| NPS (inches) | OD (inches) | WT (inches) | ID (inches) (Calculated) |

|---|---|---|---|

| 1/2 | 0.840 | 0.088 | 0.664 |

| 3/4 | 1.050 | 0.095 | 0.860 |

| 1 | 1.315 | 0.133 | 1.049 |

| 1 1/2 | 1.900 | 0.140 | 1.620 |

| 2 | 2.375 | 0.154 | 2.067 |

| 3 | 3.500 | 0.216 | 3.068 |

| 4 | 4.500 | 0.237 | 4.026 |

| 6 | 6.625 | 0.280 | 6.065 |

Elements Influencing Schedule 40 Pipe Thickness:

A number of components contribute to the exact wall thickness of Schedule 40 pipe, even throughout the standardized schedule:

-

Pipe Materials: Completely different supplies, similar to metal, copper, PVC, and CPVC, have completely different materials properties affecting their power and required thickness for a given stress score. Metal pipes, for instance, may have a unique wall thickness than PVC pipes of the identical schedule and nominal dimension resulting from variations in tensile power and different mechanical properties.

-

Manufacturing Tolerances: Manufacturing processes will not be completely exact. Slight variations in wall thickness inside a specified tolerance vary are permissible and anticipated. These tolerances are outlined by related trade requirements, guaranteeing the pipe nonetheless meets the required efficiency standards.

-

Pipe Size: Longer lengths of pipe would possibly exhibit minor variations in wall thickness because of the manufacturing course of and potential cooling results throughout manufacturing. Nevertheless, these variations are typically inside acceptable tolerances.

-

Corrosion and Put on: Over time, particularly in aggressive environments, corrosion and put on can scale back the efficient wall thickness of the pipe. This can be a essential issue to contemplate when assessing the long-term integrity of a piping system. Common inspections and upkeep are essential to mitigate these results.

Purposes of Schedule 40 Pipe:

The flexibility of Schedule 40 pipe makes it appropriate for a variety of functions throughout quite a few industries:

-

Plumbing Techniques: Schedule 40 is a standard selection for home and industrial plumbing, carrying water, wastewater, and different fluids underneath average stress. Its comparatively thick partitions present sturdiness and resistance to stress fluctuations.

-

Industrial Piping: In industrial settings, Schedule 40 pipes are used to move varied fluids, together with chemical substances, gases, and steam. The selection of fabric will depend on the fluid’s properties and the working stress and temperature.

-

Hearth Safety Techniques: For fireplace sprinkler programs, Schedule 40 pipes (typically in metal or different acceptable supplies) are used to make sure dependable water supply underneath excessive stress throughout emergencies.

-

Irrigation Techniques: In agriculture and landscaping, Schedule 40 PVC pipes are incessantly employed for irrigation, conveying water to crops and vegetation.

-

HVAC Techniques: Schedule 40 pipes can be utilized in heating, air flow, and air con (HVAC) programs for transporting refrigerant or different fluids.

-

Gasoline Distribution: Schedule 40 metal pipes are utilized in pure gasoline distribution networks, though particular rules and materials necessities apply relying on the stress and gasoline kind.

Selecting the Proper Schedule:

Whereas Schedule 40 is broadly used, deciding on the suitable schedule will depend on a number of components:

-

Working Stress: Larger working pressures necessitate thicker-walled pipes like Schedule 80 and even larger schedules.

-

Fluid Kind: The corrosiveness or different properties of the fluid being transported affect the selection of fabric and, consequently, the required schedule.

-

Temperature: Excessive-temperature functions might require specialised supplies and thicker partitions to take care of structural integrity.

-

Security Laws: Compliance with related constructing codes and security requirements is paramount. These rules typically specify the minimal required schedule for specific functions.

Past the Chart: Concerns for Sensible Utility:

Whereas the thickness chart gives important knowledge, a number of sensible concerns are essential for profitable pipe set up and system operation:

-

Correct Assist: Sufficient pipe assist is crucial to forestall sagging and stress on the pipe partitions, significantly for longer runs.

-

Right Fittings: Utilizing suitable fittings and guaranteeing correct connections are essential for stopping leaks and sustaining system integrity.

-

Growth and Contraction: For functions involving important temperature variations, allowance should be made for thermal growth and contraction to forestall stress on the pipe and connections.

-

Corrosion Safety: In corrosive environments, further safety measures, similar to coatings or cathodic safety, could also be mandatory to increase the pipe’s lifespan.

Conclusion:

Schedule 40 pipe thickness charts are indispensable instruments for engineers, plumbers, and contractors. Understanding the info introduced in these charts, together with the components influencing pipe thickness and the particular utility necessities, is essential for choosing the best pipe for the job. By contemplating all related components and adhering to finest practices, professionals can make sure the secure, dependable, and environment friendly operation of piping programs for many years to return. Keep in mind to at all times seek the advice of related codes, requirements, and producer specs to make sure compliance and optimum efficiency.

Closure

Thus, we hope this text has supplied useful insights into Decoding Schedule 40 Pipe: A Complete Information to Thickness Charts and Purposes. We hope you discover this text informative and useful. See you in our subsequent article!