Decoding The 410A Refrigerant Working Stress Chart: A Complete Information

By admin / November 14, 2024 / No Comments / 2025

Decoding the 410A Refrigerant Working Stress Chart: A Complete Information

Associated Articles: Decoding the 410A Refrigerant Working Stress Chart: A Complete Information

Introduction

With nice pleasure, we’ll discover the intriguing matter associated to Decoding the 410A Refrigerant Working Stress Chart: A Complete Information. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Decoding the 410A Refrigerant Working Stress Chart: A Complete Information

R-410A, a hydrofluoroolefin (HFO) mix, has develop into a prevalent refrigerant in air-con and refrigeration methods, changing R-22 resulting from its larger effectivity and decrease environmental influence (although nonetheless a potent greenhouse fuel). Understanding its working pressures is essential for secure and environment friendly system operation, troubleshooting, and upkeep. This text delves into the intricacies of the 410A working strain chart, explaining its elements, interpretation, and sensible purposes.

Understanding the Fundamentals: Stress-Temperature Relationship in Refrigerant Techniques

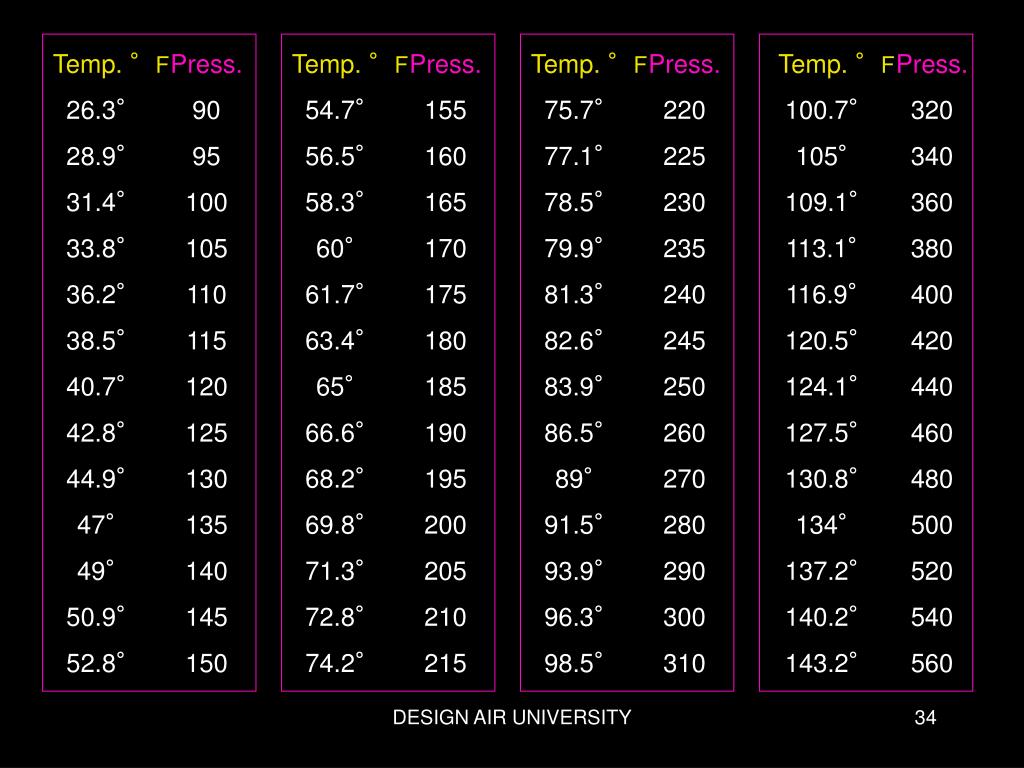

Earlier than diving into the specifics of the 410A chart, it is essential to know the basic relationship between strain and temperature in refrigerant methods. Refrigerants function on a thermodynamic cycle, transitioning between totally different phases (liquid, vapor, and superheated vapor) as they take in and launch warmth. This part change is straight linked to strain and temperature. A pressure-temperature (P-T) chart visually represents this relationship, displaying the strain a refrigerant will exert at a given temperature for a selected part.

For 410A, this relationship is considerably totally different from that of R-22 or different refrigerants. 410A is a zeotropic mix, which means its composition modifications barely because it evaporates and condenses. This zeotropic nature impacts its pressure-temperature relationship, resulting in a barely wider strain vary at a given temperature in comparison with azeotropic refrigerants (like R-22). This attribute necessitates a exact understanding of the 410A P-T chart for correct system analysis and upkeep.

Deconstructing the 410A Working Stress Chart

A typical 410A working strain chart shows strain (normally in kilos per sq. inch – PSI or kilopascals – kPa) on the vertical axis and temperature (in levels Fahrenheit or Celsius) on the horizontal axis. The chart normally consists of a number of key strains:

-

Saturation Curve: That is arguably essentially the most essential line on the chart. It represents the strain at which 410A transitions between its liquid and vapor phases at a given temperature. Factors beneath the saturation curve point out the refrigerant is in a subcooled liquid state, whereas factors on the curve characterize a saturated liquid-vapor combination, and factors above the curve point out superheated vapor.

-

Subcooling Line: This line reveals the strain of the liquid refrigerant beneath its saturation temperature. Subcooling is fascinating because it will increase system effectivity and reduces the chance of liquid refrigerant getting into the compressor (liquid slugging), which may trigger critical injury.

-

Superheat Line: This line signifies the strain of the refrigerant vapor above its saturation temperature. Superheat can be essential for environment friendly operation. Inadequate superheat can result in liquid getting into the compressor, whereas extreme superheat signifies potential points like inadequate refrigerant cost or restricted airflow.

-

Stress-Temperature Relationship for Completely different System Parts: Some charts would possibly embrace particular strain ranges for various elements just like the evaporator, condenser, and compressor. These ranges assist technicians decide if the system is working inside its designed parameters.

Deciphering the Chart: Sensible Functions

The 410A strain chart serves a number of sensible functions:

-

Refrigerant Cost Dedication: By measuring the system’s strain and temperature on the liquid line and suction line, technicians can decide if the refrigerant cost is sufficient. Low strain would possibly point out a refrigerant leak or inadequate cost, whereas excessive strain might counsel overcharging or a system malfunction.

-

Troubleshooting System Malfunctions: Deviations from the anticipated pressure-temperature relationship can pinpoint varied system points. For instance, excessive condenser strain would possibly point out a unclean condenser coil, defective condenser fan motor, or restricted airflow. Low suction strain might level to a refrigerant leak, restricted evaporator airflow, or a defective metering machine.

-

System Effectivity Evaluation: The chart helps consider the system’s effectivity. Enough subcooling and superheat are important for optimum efficiency. Deviations from the perfect ranges can point out areas for enchancment, reminiscent of optimizing airflow or addressing element malfunctions.

-

Security Precautions: Understanding the working pressures is important for security. Exceeding the utmost allowable strain can result in system failure and potential hazards. The chart offers a reference level to make sure the system operates inside secure limits.

Elements Affecting 410A Working Pressures

A number of components affect the precise working pressures in a 410A system, even when the temperature is thought:

-

Ambient Temperature: Larger ambient temperatures improve condenser strain, whereas decrease ambient temperatures lower it.

-

Refrigerant Cost: An overcharged system will exhibit larger pressures, whereas an undercharged system will present decrease pressures.

-

Airflow: Restricted airflow throughout the evaporator and condenser coils can considerably have an effect on pressures. Inadequate airflow will increase strain within the condenser and reduces strain within the evaporator.

-

System Parts: Malfunctioning elements like compressors, growth valves, or capillary tubes can have an effect on the pressure-temperature relationship.

-

Elevation: Altitude impacts the boiling level of the refrigerant, thus influencing the working pressures. Larger elevations usually lead to decrease pressures.

Limitations of the Chart

Whereas the 410A strain chart is a precious software, it is important to acknowledge its limitations:

-

Simplified Illustration: The chart offers a simplified illustration of a posh thermodynamic course of. It would not account for all variables affecting system strain.

-

Accuracy Dependence: The accuracy of the chart’s interpretation is determined by the accuracy of the strain and temperature measurements. Inaccurate readings can result in misinterpretations and incorrect diagnoses.

-

Not a Substitute for Complete Coaching: The chart is a useful software however should not change correct coaching and expertise in refrigeration and air-con methods.

Conclusion

The 410A working strain chart is an indispensable software for HVAC technicians. Understanding its intricacies, decoding its information, and contemplating the influencing components are essential for environment friendly system operation, correct troubleshooting, and guaranteeing secure working practices. Whereas the chart offers precious insights, it is important to mix its use with sensible expertise, correct coaching, and the applying of sound diagnostic procedures for optimum outcomes. All the time prioritize security and seek the advice of related trade requirements and tips when working with refrigeration methods. Bear in mind, this data is for instructional functions solely and shouldn’t be thought-about an alternative choice to skilled HVAC coaching and steerage.

Closure

Thus, we hope this text has offered precious insights into Decoding the 410A Refrigerant Working Stress Chart: A Complete Information. We hope you discover this text informative and useful. See you in our subsequent article!