Mastering The Goodman Warmth Pump Charging Chart: A Complete Information To 410A Refrigerant

By admin / November 18, 2024 / No Comments / 2025

Mastering the Goodman Warmth Pump Charging Chart: A Complete Information to 410A Refrigerant

Associated Articles: Mastering the Goodman Warmth Pump Charging Chart: A Complete Information to 410A Refrigerant

Introduction

With nice pleasure, we’ll discover the intriguing subject associated to Mastering the Goodman Warmth Pump Charging Chart: A Complete Information to 410A Refrigerant. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Mastering the Goodman Warmth Pump Charging Chart: A Complete Information to 410A Refrigerant

Goodman warmth pumps, identified for his or her reliability and effectivity, rely closely on the exact cost of R-410A refrigerant for optimum efficiency. Understanding and using the Goodman warmth pump charging chart is essential for technicians to make sure correct system operation, stop expensive repairs, and maximize the lifespan of the unit. This text delves deep into the intricacies of the R-410A charging chart, offering a complete information for each skilled technicians and people looking for a greater understanding of this important facet of HVAC upkeep and restore.

Understanding R-410A Refrigerant:

R-410A is a hydrofluoroolefin (HFO) mix, particularly a zeotropic combination of difluoromethane (R-32) and pentafluoroethane (R-125). In contrast to R-22, its predecessor, R-410A is non-ozone-depleting and boasts greater effectivity. Nevertheless, its zeotropic nature signifies that it does not have a single boiling level; the combination boils over a spread of temperatures. This necessitates exact charging procedures, making the Goodman charging chart indispensable.

The Significance of Correct Refrigerant Cost:

An improperly charged Goodman warmth pump can undergo from a large number of issues, together with:

- Lowered Cooling Capability: Undercharging results in inadequate refrigerant move, leading to weak cooling and elevated vitality consumption.

- Elevated Power Consumption: Each undercharging and overcharging can considerably improve vitality consumption, resulting in greater utility payments.

- System Harm: Overcharging may cause excessive head stress, doubtlessly damaging the compressor and different elements.

- Freezing: Undercharging may cause evaporator coils to freeze, hindering warmth switch and doubtlessly damaging the system.

- Quick Biking: Improper refrigerant cost can result in frequent on-off biking, lowering effectivity and rising put on and tear on the compressor.

- Lowered Heating Capability: Just like cooling, inadequate refrigerant will influence the heating efficiency, resulting in insufficient heat.

Deciphering the Goodman Warmth Pump Charging Chart:

The Goodman charging chart, sometimes discovered within the unit’s set up and repair guide, isn’t a easy desk. It is a complicated doc that requires cautious interpretation. Key components to grasp embody:

- System Capability (BTU/hr): The chart can be organized primarily based on the warmth pump’s cooling capability in British Thermal Models per hour (BTU/hr). It is a crucial parameter for figuring out the proper refrigerant cost.

- Line Dimension (Diameter): The diameter of the refrigerant traces considerably impacts the refrigerant cost. Bigger traces require extra refrigerant to fill the system successfully.

- Liquid Line Temperature: It is a essential measurement taken on the liquid line close to the metering machine (growth valve or metering machine). The chart typically gives goal liquid line temperatures for optimum efficiency.

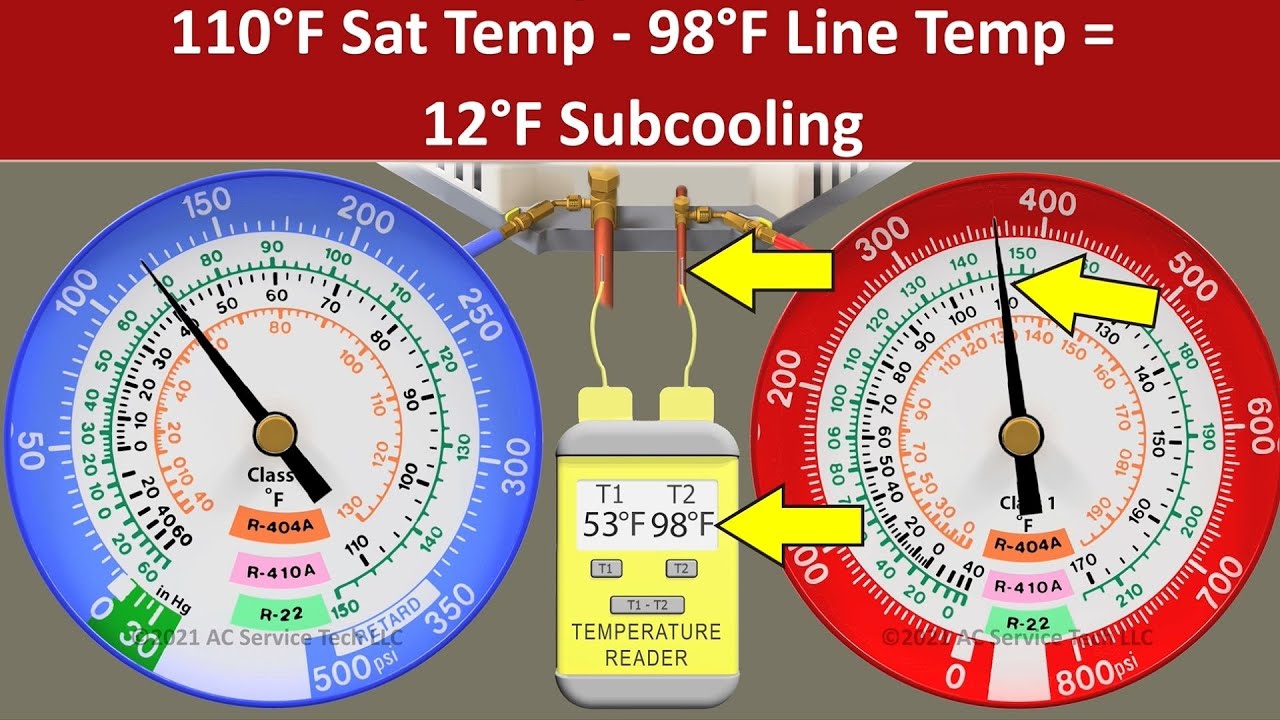

- Subcooling: That is the distinction between the liquid line temperature and the saturation temperature on the corresponding system stress. Subcooling ensures that the refrigerant is absolutely condensed earlier than getting into the metering machine.

- Superheat: That is the distinction between the suction line temperature and the saturation temperature on the corresponding suction stress. Superheat is crucial for guaranteeing correct refrigerant move and stopping evaporator coil freezing.

- Ambient Temperature: The ambient temperature considerably impacts refrigerant cost necessities. The chart could present changes primarily based on various outside temperatures.

Utilizing the Chart: A Step-by-Step Method:

- Determine the Unit Mannequin and Capability: Find the mannequin quantity and cooling capability (BTU/hr) on the unit’s nameplate.

- Decide Line Sizes: Measure the diameter of each the liquid and suction traces.

- Examine Ambient Temperature: File the outside ambient temperature.

- Find the Applicable Part: Use the mannequin quantity, capability, line sizes, and ambient temperature to search out the proper part inside the Goodman charging chart.

- Decide the Goal Refrigerant Cost: The chart will present the really helpful refrigerant cost in ounces or kilos.

- Measure Present Refrigerant Cost: Use a refrigerant scale to precisely measure the prevailing refrigerant cost within the system.

- Add or Take away Refrigerant: Rigorously add or take away refrigerant as wanted to succeed in the goal cost, following correct security procedures.

- Measure Superheat and Subcooling: After charging, measure the superheat and subcooling to confirm correct refrigerant ranges. These measurements are essential for fine-tuning the cost.

- File Measurements: Doc all measurements, together with ambient temperature, liquid line temperature, suction line temperature, pressures, and refrigerant cost, for future reference.

Superior Methods and Issues:

- Digital Scales: Using digital scales ensures exact refrigerant measurement, minimizing errors and enhancing accuracy.

- Refrigerant Restoration and Recycling: At all times get better and recycle refrigerant in keeping with EPA rules. That is essential for environmental safety and accountable HVAC practices.

- Vacuuming the System: Earlier than charging, it is important to totally evacuate the system to take away air and moisture, which may severely influence system efficiency and longevity.

- Leak Detection: Common leak detection is crucial to take care of optimum refrigerant ranges and stop untimely system failure. Leak detection instruments will help establish even small leaks.

- Understanding Strain-Temperature Charts: Whereas the Goodman charging chart is restricted to their items, understanding common pressure-temperature charts for R-410A gives precious context and permits for cross-referencing.

Security Precautions:

Working with refrigerants requires stringent security precautions. At all times put on acceptable private protecting tools (PPE), together with security glasses, gloves, and respiratory safety. Guarantee ample air flow when working with refrigerants. By no means work on a stay system with out correct coaching and security measures.

Conclusion:

The Goodman warmth pump charging chart is an important instrument for guaranteeing optimum efficiency and longevity of Goodman warmth pump techniques. Understanding its intricacies, coupled with correct coaching and security procedures, empowers technicians to precisely cost the system, resulting in improved effectivity, decreased vitality consumption, and enhanced buyer satisfaction. Keep in mind that this data is for instructional functions; all the time check with the official Goodman service guide to your particular unit mannequin for exact directions and security tips. Improper dealing with of refrigerants could be harmful; all the time prioritize security and search skilled help if uncertain about any facet of the method.

Closure

Thus, we hope this text has supplied precious insights into Mastering the Goodman Warmth Pump Charging Chart: A Complete Information to 410A Refrigerant. We respect your consideration to our article. See you in our subsequent article!