Mastering X-bar And R Charts In Excel: A Complete Information To Course of Management

By admin / July 4, 2024 / No Comments / 2025

Mastering X-bar and R Charts in Excel: A Complete Information to Course of Management

Associated Articles: Mastering X-bar and R Charts in Excel: A Complete Information to Course of Management

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to Mastering X-bar and R Charts in Excel: A Complete Information to Course of Management. Let’s weave attention-grabbing data and supply recent views to the readers.

Desk of Content material

Mastering X-bar and R Charts in Excel: A Complete Information to Course of Management

Statistical Course of Management (SPC) is a vital methodology for monitoring and bettering the standard of processes. Among the many varied SPC charts, the X-bar and R chart mixture stands out as a robust instrument for analyzing steady information and figuring out sources of variation. This text gives a complete information to understanding, creating, and decoding X-bar and R charts utilizing Microsoft Excel, equipping you with the talents to successfully handle course of stability and improve general high quality.

Understanding X-bar and R Charts

X-bar and R charts are utilized in pairs. They’re designed for monitoring the central tendency and variability of a course of, respectively. Let’s break down every chart’s operate:

-

X-bar Chart (Common Chart): This chart screens the typical (imply) of a course of over time. It tracks the central tendency, revealing whether or not the method common is shifting or remaining secure. Vital shifts point out potential issues that want investigation.

-

R Chart (Vary Chart): This chart screens the vary (the distinction between the most important and smallest values) inside subgroups of knowledge. It tracks the variability or dispersion of the method. Elevated vary suggests elevated variability, probably indicating instability or out-of-control situations.

The ability of utilizing these charts collectively lies of their complementary nature. A secure course of will exhibit a secure common (X-bar chart) and a secure vary (R chart). Conversely, an unstable course of will present instability in both or each charts. Analyzing each concurrently gives a extra full image of course of conduct than both chart alone.

Information Necessities and Subgrouping

Earlier than creating X-bar and R charts, it is important to grasp the information necessities and the important idea of subgrouping.

-

Information Sort: These charts are designed for steady information, which suggests information that may tackle any worth inside a given vary (e.g., weight, size, temperature). Discrete information (e.g., variety of defects) requires completely different management charts like p-charts or c-charts.

-

Subgrouping: Information must be collected in subgroups, that are small samples taken at common intervals. The dimensions of the subgroups (sometimes 4-5 information factors) is essential. Smaller subgroups are extra delicate to small shifts within the course of common, whereas bigger subgroups are much less delicate however present a extra secure estimate of variability. The selection of subgroup dimension depends upon the particular course of and the specified sensitivity. The subgroups must be collected rationally, representing the standard operation of the method. Keep away from mixing information from completely different shifts, machines, or operators inside a single subgroup.

Creating X-bar and R Charts in Excel

Whereas devoted statistical software program gives superior options, Excel gives enough performance for creating and decoding primary X-bar and R charts. This is a step-by-step information:

-

Information Entry: Arrange your information in a spreadsheet. Every column represents a subgroup, and every row inside a column represents an information level inside that subgroup.

-

Calculate Subgroup Statistics: For every subgroup, calculate the typical (X-bar) and the vary (R). You need to use Excel’s built-in features:

AVERAGE(vary): Calculates the typical of a variety of cells.MAX(vary): Finds the utmost worth in a variety of cells.MIN(vary): Finds the minimal worth in a variety of cells.=MAX(vary)-MIN(vary): Calculates the vary.

-

Calculate Total Statistics: Calculate the general common of the X-bar values (X-double bar) and the typical of the R values (R-bar). These are essential for calculating management limits.

-

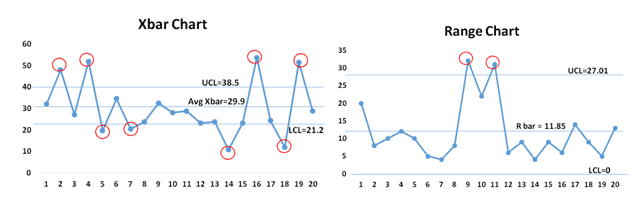

Calculate Management Limits: The management limits for the X-bar and R charts are calculated utilizing management chart constants (A2, D3, D4) which rely on the subgroup dimension. These constants are available in statistical tables or on-line sources. The formulation are:

-

X-bar Chart:

- Higher Management Restrict (UCL): X-double bar + A2 * R-bar

- Decrease Management Restrict (LCL): X-double bar – A2 * R-bar

- Heart Line (CL): X-double bar

-

R Chart:

- Higher Management Restrict (UCL): D4 * R-bar

- Decrease Management Restrict (LCL): D3 * R-bar

- Heart Line (CL): R-bar

-

-

Create the Charts: Use Excel’s charting capabilities to create two separate charts: one for the X-bar information and one for the R information. Plot the subgroup averages (X-bar) and ranges (R) in opposition to the subgroup quantity. Add the calculated management limits (UCL, LCL, and CL) to every chart as horizontal traces.

-

Interpret the Charts: Study the charts for any factors outdoors the management limits or patterns that counsel instability. Factors outdoors the management limits point out potential particular trigger variation, requiring investigation. Patterns similar to developments, cycles, or stratification additionally counsel course of instability.

Deciphering X-bar and R Charts

As soon as the charts are created, decoding them is essential for figuring out course of points. A number of key indicators sign potential issues:

-

Factors outdoors the management limits: Any information level falling outdoors the higher or decrease management limits signifies a big deviation from the anticipated course of conduct. These factors warrant speedy investigation to establish and eradicate the basis explanation for the variation.

-

Developments: A constant upward or downward development suggests a gradual shift within the course of common or variability. This might be because of instrument put on, materials degradation, or different elements that require consideration.

-

Cycles: Recurring patterns of excessive and low values counsel cyclical variations, probably associated to time of day, day of the week, or different periodic influences.

-

Stratification: Clustering of factors above or under the middle line signifies that the method just isn’t persistently performing on the goal worth.

-

Uncommon patterns: Another uncommon patterns, similar to runs of factors above or under the middle line, must also be investigated.

Excel’s Information Evaluation Toolpak

Excel’s Information Evaluation Toolpak can simplify the method of making X-bar and R charts. Nevertheless, it does not immediately generate these charts; as a substitute, it gives the mandatory calculations. You’d nonetheless have to create the charts manually utilizing Excel’s charting options. To allow the Information Evaluation Toolpak, go to File > Choices > Add-Ins > Handle: Excel Add-ins > Go. Then, test the "Evaluation ToolPak" field and click on OK.

Limitations and Concerns

Whereas X-bar and R charts are invaluable instruments, they’ve limitations:

-

Assumption of Normality: The management limits are calculated primarily based on the idea of usually distributed information. If the information considerably deviates from normality, the management limits will not be correct.

-

Subgroup Dimension: The selection of subgroup dimension impacts the sensitivity of the charts. Too small a subgroup dimension can result in false alarms, whereas too massive a subgroup dimension might masks refined shifts within the course of.

-

Frequent Trigger vs. Particular Trigger Variation: Distinguishing between frequent trigger (inherent to the method) and particular trigger (assignable) variation is essential. Management charts assist establish particular trigger variation, however additional investigation is required to find out the basis trigger.

Conclusion

X-bar and R charts are indispensable instruments for monitoring and bettering course of high quality. By understanding the ideas behind these charts and using Excel’s capabilities, you’ll be able to successfully monitor course of efficiency, establish potential issues, and implement corrective actions to attain larger stability and effectivity. Keep in mind that the interpretation of management charts requires cautious consideration of the context and potential limitations, making it a invaluable talent for high quality professionals and anybody concerned in course of enchancment initiatives. Whereas Excel gives a handy platform, think about using specialised statistical software program for extra superior analyses and options.

Closure

Thus, we hope this text has supplied invaluable insights into Mastering X-bar and R Charts in Excel: A Complete Information to Course of Management. We thanks for taking the time to learn this text. See you in our subsequent article!